Lichfields has been successful in obtaining a positive determination from Kirklees Council for a proposal by Johnson Wellfield to extract a million tonnes of sandstone over a term of 20 years from a new 24ha mineral working area at Crosland Moor, Huddersfield.

Stone-built properties are a familiar feature of the northern landscape, no less so than in the former mill towns of the West Riding, where the wealth of the area derived from the local manufacturing industries was displayed in the form of magnificent civic, commercial and community buildings.

The local quarries from which dimension stone for those buildings was extracted are often long since exhausted. However, new stone workings now operate to meet today’s demand for the high quality ashlar sandstones known in the trade as ‘Yorkstone’; they are used in high specification architectural and masonry applications, often for heritage projects, not only in the immediate area but also throughout the UK.

Johnsons Wellfield, based at Crosland Hill, Huddersfield is the UK’s leading producer of natural Yorkstone building products

[1], extracted from its Crosland Moor minerals workings and located in the locally-occurring Rough Rock sandstone outcrop. With its presence in Huddersfield for over 150 years, Johnsons Wellfield’s history is interwoven with the local built vernacular. More recently, its high quality ashlar masonry products have been used locally, with considerable acclaim, as part of Huddersfield University’s new Oastler Building, and for paving in the St Georges Square adjacent to the town’s suitably impressive Grade 1 listed railway station. Further afield, the company’s stone has been used recently in paving along the Thames Embankment, at the National Cenotaph and within Westminster Abbey.

St Georges Square, Huddersfield

Image courtesy of Myers Group Ltd

To maintain its leading position, Johnsons Wellfield has made significant investment in new stone processing technology to meet challenging customer requirements. Advanced robotic masonry equipment now enables the manufacture of both intricate and specification-perfect architectural features, placing the firm at the forefront of this business sector. An established, skilled workforce of over 100 employees makes this happen, in turn significantly contributing to the local economy.

Ashlar Block Processing

Image courtesy of Myers Group Ltd

Without a guaranteed and continuous supply of suitable stone block, the raw material in the ground from which the building products are derived, production would ultimately cease. Johnsons Wellfield- like all other minerals operators - therefore need to plan ahead and ensure that there will be continuity of supply of permitted reserves to sustain its business into the future.

It can be a significant step between identifying suitable resource and converting this into a permitted minerals reserve, particularly given that minerals can only be worked where they occur. In preparing a scheme for a planning application, there are often tensions between the sensitivities of the local environment (such as historic and conservation area assets and Special Protection Area designations), nearby settlements and justifying the need to extract an available and viable minerals deposit which outcrops in a particular location. Potential objectors may say why here, why not somewhere else?

Faced with exhaustion of their present minerals reserve, Johnsons Wellfield identified a new 24 ha extraction area located nearby, and secured the ownership rights to it. The Crosland Moor site offered a proven resource of a million tonnes of ashlar block, capable of sustaining Johnsons Wellfield’s needs over the next 20 years. The challenge was to design a scheme which met policy considerations particularly given its countryside location, on an unallocated site within the Green Belt.

A team experienced in preparing minerals planning applications was assembled by Lichfields to address the sensitivities presented by the proposal, not least: the proximity of the neighbouring settlement and conservation area of South Crosland; the upland landscape context; and biodiversity interests. Taking on board feedback from a community consultation event, a number of options for the development were considered through the process of environmental impact assessment and a scheme was designed which incorporated mitigation measures, thereby minimising potential impacts from arising from the extraction of stone and site restoration. Such measures include: the restriction of hours of working; the implementation of dust suppression measures and the application of noise controls to mobile plant used in the extraction process. An important design consideration was to ensure that the supply of ground water serving historic water troughs and spring-fed domestic water supplies located in the local area were not affected by the proposed development.

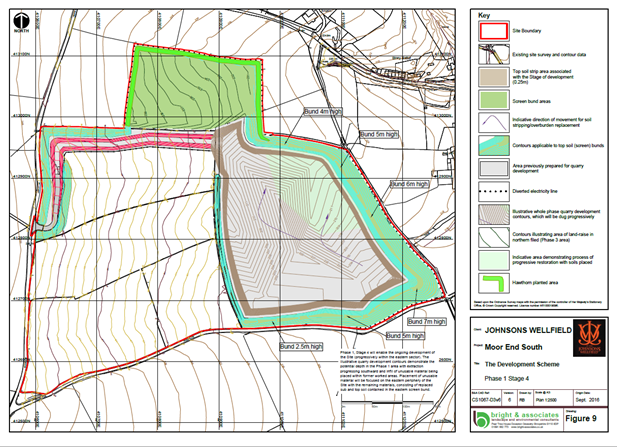

The design of the scheme of phased extraction, screen bunding and restoration, together with state-of-the-art operational controls and the restriction of associated heavy goods vehicles movements mean that the operation will be low key in operation and will result in biodiversity enhancement throughout and beyond the restoration phases. Whilst the proposal was to return the site back to productive upland farmland following the completion of extraction and restoration, the statutory authorities required the inclusion of meaningful biodiversity enhancement within the scheme. Within the scheme, this takes the form of provision of habitat for hare and the creation of a wet scrape which will be of value to invertebrates.

The site will ultimately be restored back to agricultural pasture in this countryside location, employing the existing configuration of drystone walling and gating, suitable for onward sale for farming in perpetuity. An undertaking to create a new public footpath across the restored site will add much needed connectivity to the local network.

Extract from the Scheme of Phased Extraction

The proposal has now been determined positively by the Kirklees Strategic Planning Committee, with members having balanced the level of public support for the scheme (which reflected the need for the continued local employment of a skilled workforce) and the significant investment in manufacturing technology and the local economy coupled with concerns over the potential impacts of minerals extraction such as traffic, dust and noise over the permitted term.

Development is due to commence on-site in 2019, following the discharge of pre-commencement planning conditions and the completion of working at Johnsons Wellfields existing minerals operation which the Crosland Moor site will replace.

Lichfields provides: planning; technical team coordination; environmental impact assessment; economics and community engagement services to the project.

[1] https://www.johnsons-wellfield.co.uk/